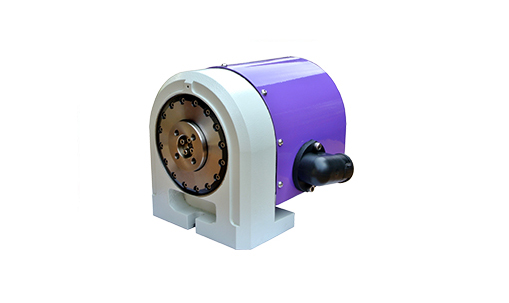

EDD-125AP

Direct Drive Rotary Table (0.001°)

EDD-125AP

Vertical Use

EDD-125AP direct drive rotary is specifically designed for processing indexing manufacture tasks, with a DD (direct drive) servo motor and minimum indexing degree of 0.001 degrees further enhancing its precision, allowing for extremely accurate positioning and alignment of workpieces or tools. The rotary table can achieve high speeds, with a 90-degree division time of less than 1 second. This rapid movement capability is beneficial for tasks that require quick indexing or positioning, improving overall efficiency and productivity.

This direct drive rotary table also offers high repeatability, ensuring consistent and reliable performance over time for maintaining quality standards and achieving consistent results in manufacturing processes.

EDD-125AP direct drive rotary can be tailored to meet specific accuracy requirements, welcome to inquiry!

| Use Method | Vertical use |

|---|---|

| Cooling Circuit Reserve | - |

| Cooling Type | Natural cooling |

| Clamp Method | Pneumatic 5 kg/cm2 |

| Faceplate Dimension | - |

| Applicable Panel | Ø125 mm (Optional) |

| Spindle through hole diameter | - |

| Centre Height | 110 mm |

| Solenoid & Detection | Already included |

| Encoder format | Heidenhain Serial Interface , EnDAT 2.2/22 25bit |

| NIKON Serial abs interface 24bit | |

| Max. Speed (1sec) | 200 rpm |

| continuous r.p.m | 100 rpm |

| Max. Rated current (1sec) | 8.58 A |

| Cont. Rated current | 2.86 A |

| Max. Rated torque (1sec) | 18.6 Nm |

| Cont. Rated torque | 6.2 Nm |

| Min. Increment Unit | 0.001° |

| Indexing Accuracy | ±25 Arc.Sec. |

| Repeatability | Within 10 Arc.Sec. |

| Clamp Force | 19 kgf-m |

| Net Weight (Without motor) | 16 kg |

Max. Workpiece load capacity (without tailstock)

|

W:10kg |

| D:125mm | |

| L:200mm |