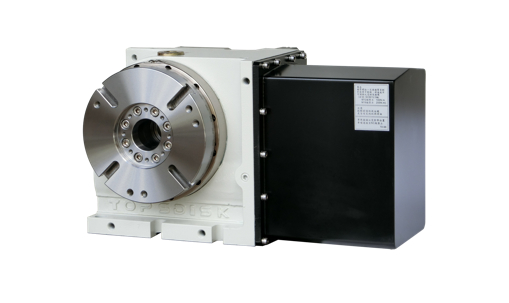

FCM-200AP / FCM-200AH

Preload Barrel Cam Type Rotary Table(0.001 degree)

FCM-200AP / FCM-200AH

Vertical Use

- Preloaded barrel cam mechanism, backlash approaches zero.

- Rolling friction transmission extend operation life.

- The transmission element is made of steel, which is more rigid than copper and stronger eccentric load.

- Double action pneumatic or hydraulic brake mechanism to ensure fully unclamp.

- Standard pressure switch reduces maintenance opportunities.

- Solenoid valve and pressure switch are installed outside to avoid moisture inside the rotary table to damage electrical components.

- Directly equipped with the absolute motor, no need to Zero return when starting up.

| Specification | FCM-200AP | FCM-200AH | |

|---|---|---|---|

| Use Method | Vertical | ||

| Clamp Method | Pneumatic 5kg/cm2 | Hydraulic 35kg/cm2 | |

| Faceplate Dimension | Ø200mm | ||

| Spindle through hole | Ø40mm | ||

| Faceplate centre hole | Ø95mmH7 | ||

| Centre Height | 160mm | ||

| Faceplate T-slot width | 12mmH7 | ||

| Position key | 18mmh7 | ||

| Absolute servo motor |

FANUC | α4i/β8i Straight shaft | |

| MELDAS | HF-104S | ||

| Yaskawa | SGM7G-09 | ||

| Siemens | 1FK-7060-****-1RG1 | ||

| Reduction ratio | 1/60 | ||

| Min. Increment Unit | 0.001° | ||

| Indexing Accuracy | ±15(Arc.Sec.) | ||

| Repeat Accuracy | 10(Arc.Sec.) | ||

| Clamp Force | 30kgf-m | 144kgf-m | |

| * Maximum RPM (3 sec) | 50rpm@motor3000rpm | ||

|

* Max. Workpiece of Capacity (within faceplate diameter) |

Vertical only | 80kg | |

| Vertical (with tailstock) |

160kg | ||

| * Cam torque | Continuous | 210Nm@10rpm | |

| Maximum | 458Nm | ||

| Net weight | without motor but with faceplate | 76kg | 81kg |

Note:* above table is the data within the diameter of faceplate, if it exceeds the faceplate, the same maximum inertia value must be calculated as the limit.

| Balanced Load | No Tailstock |  |

W:80kg D:Ø200mm L: 260mm |

|---|---|---|---|

| using Faceplate Tailstock |  |

W:160kg D:Ø200mm L: 700mm |

|

| using manual Tailstock |  |

W:100kg D:Ø200mm L: 700mm |

|

| Eccentric Load | using Tailstock |  |

Eccentric Load= l x W W:2.4kg-m |

Note:The maximum load value is only one of the three conditions (weight W, rotation diameter D, length L) can be satisfied.

◆ Customers or machines need to prepare :

- The hydraulic unit at least one circuit (DC24V/2B2 solenoid valve).

- The machine must has the fourth axis function, absolute motor and amplifier.

- Conduit Cable (Length depends on machine condition)

- Two oil pipes. (Length depends on machine condition)

◆ Standard accessories:

- Pressure switch, 5m cable.

- Three bolt sets and T-blocks. (match with position key 18mm; T-slot pitch 100 and 125mm)

- Cable seat (conduit cables provided by customer)

unit:mm

| FCM-200A | total width(A) | Total thickness(B) | Total height(C) | Centre height(D) | Spindle through hole(K) | Plate outer diameter(H) | Spindle length(L) | Screw Pitch, Slot Width(E) |

|---|---|---|---|---|---|---|---|---|

| No faceplate | 482 | 231 | 270 | 160 | Ø40 | Ø90 | 190 | 200 , 18 |