TD-170P

NC Rotary Table (0.001°)

TD-170P

Standard Series

- Adopted high-tech Cross Roller Bearing.

- Pneumatic clamping adopted patented disk-clamping system (Taiwan PAT. : 217736 ) to enlarge clamping force and ensure heavy-duty continuous cutting.

- The feature of wear resistant alloy Dual-Lead Worm Gear is high mechanical e-ciency of power transmission, high indexing accuracy, and easy adjusted on the backlash.

- Driven by the servo Motor. E-ciently in position, high accuracy, Low noise and suitable for any angles working piece.

- It can be connected with CNC machine as a 4th Axis or matched with Single Axis Controller as an additional Axis.

| Use Method | Vertical/Horizontal use | |

|---|---|---|

| Clamp Method | Pneumatic 5kg/cm2 | |

| Faceplate Dimension | Ø170mm | |

| Spindle Through Hole Diameter | Ø45mm | |

| Faceplate Centre Hole Diameter | Ø50H7mm | |

| Centre Height | 135mm | |

| Faceplate T-Slot Width | 12H7mm | |

| Position Key | 14h7mm | |

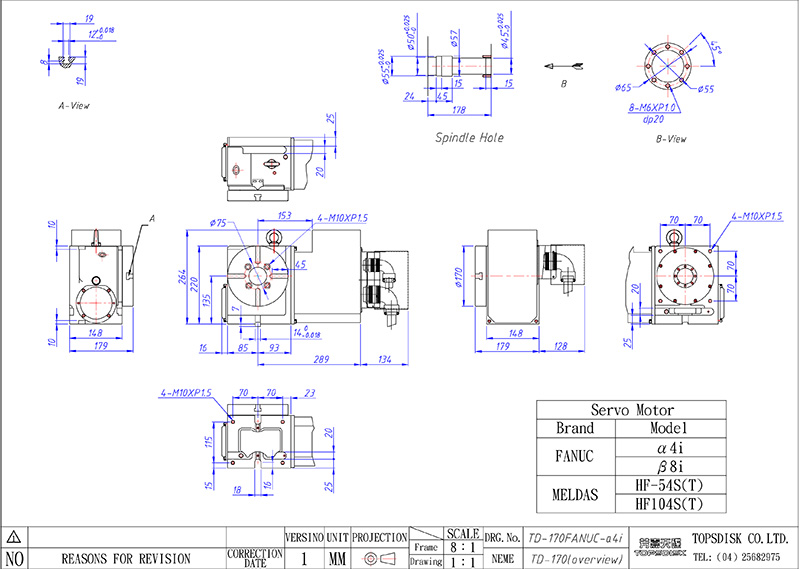

| Servo Motor | • FANUC | α4i / β8i |

| • MELDAS | HF54T | |

| Total Speed Reduction Ratio | 1/72, 1/90 | |

| Min. Increment Unit | 0.001° | |

| Indexing Accuracy | 30 (Arc. Sec.) | |

| Repeatability | 4 (Arc. Sec.) | |

| Clamp Force | 16kgf-m | |

| Max. Torque Capacity of Worm Gear | 27kgf-m | |

| Max. Workpiece of Capacity | •Workpiece Vertical (With Tailstock) |

75(150)kg |

| • Horizontal | 150kg | |

| Net Weight (Without motor) | 40kg | |